The control starts up in Incremental jog mode. In order to jog the axes in continuous movement, you need to press the INCR/CONT key to switch from incremental to continuous jog mode.

The machine is a five-axis horizontal boring mill. It can operate in either a horizontal format, or in a vertical format using a right-angle head attached to the spindle face.

In the horizontal milling format, axis movement is as follows:

| X | Table left/right |

| Y | Head up/down |

| Z | Bar in/out |

| W | Saddle out/in |

| B | Rotary Table CW/CCW |

In the vertical milling format, axis movement is as follows:

| X | Table left/right |

| Y | Saddle in/out |

| Z | Head up/down |

| B | Rotary Table CW/CCW |

The Machine Home position is with the table fully to the right; head all the way up; saddle away from the column; and, if in the horizontal format, bar fully retracted.

|

The control starts up in Incremental jog mode. In order to jog the axes in continuous movement, you need to press the INCR/CONT key to switch from incremental to continuous jog mode. |

The switch between horizontal milling and vertical milling formats is accomplished by swapping control configuration and parameter values, and of course by installing or removing the right-angle head.

After swapping configuration and parameter files, the control must be shut down, powered off, and powered back up in order for the change to take effect.

It will be easier to install and remove the right-angle head while the control is configured for horizontal milling operation. Therefore you should install the right-angle head just before switching the control from horizontal to vertical; and you should remove the right-angle head after switching the control back from vertical to horizontal.

This is because in horizontal mode you can control the bar, as the Z axis. In vertical mode you cannot move the bar.

The work light

will come on automatically when the machine is powered up.

The work light

will come on automatically when the machine is powered up.

You can turn the light off and on by pressing the work light (Aux2) key on the jog panel.

The Horizontal spindle has a power-operated drawbar.

To insert a tool:

To remove a tool:

You can control spindle rotation speed and direction manually with jog panel keys, or automatically with program codes.

The spindle must be in Auto mode in order to use programmed M and S codes. The spindle must be in Manual mode in order to use the jog panel keys.

|

Switch between Auto and Manual control modes. |

In manual mode, you can control operation and direction with these keys:

|

Select spindle forward (CW) |

|

Select spindle reverse (CCW) |

|

Start spindle |

|

Stop spindle |

In Auto mode, you can control operation and direction with these codes:

| M3 | Start spindle forward (CW tool) |

| M4 | Start spindle reverse (CCW tool) |

| M5 | Stop spindle |

| Snnn | Set speed to nnn RPM |

In either mode, you can further control speed with these keys:

|

Increase speed |

|

Set speed to 100% of programmed speed (Auto mode) or to half of maximum speed (Manual mode) |

|

Decrease speed |

The machine has a hydraulically shifted 4-speed headstock.

Gear shifting is always done with M functions, either in a CNC program or at the MDI prompt:

M44 |

High range | (641-1340 RPM) |

| M43 | Medium-high range | (321-640 RPM) |

| M42 | Medium-low range | (161-320 RPM) |

| M41 | Low range | (1-160 RPM) |

| M49 | Shift to best range for programmed RPM |

In automatic operation, the M3 and M4 codes call M49 at every spindle start, automatically shifting ranges as needed.

You only need to enter M41 - M44 for manual operations.

M41 - M44 require that spindle control be in Auto mode. For use in Manual mode, switch to Auto; run the gear shift M function; and switch back to Manual.

In manual operations, it is possible to run slower than the minimum for each range listed above. For example, the minimum possible speed in high range is about 60 RPM. Thus extra shifting can be avoided, as long as full torque is not required.

When the machine is in the vertical milling format, spindle speed is limited to 600 RPM. This is the speed limit of the right-angle head.

There are axis holding clamps on the X (table), Y (head), W (saddle) and B (rotary) axes. You can apply and release the clamps with the following M functions:

M32 |

Clamp table base (X axis) |

M33 |

Unclamp table base (X axis) |

M34 |

Clamp head (horizontal Y axis, vertical Z axis) |

M35 |

Unclamp head (horizontal Y axis, vertical Z axis) |

M36 |

Clamp saddle (horizontal W axis, vertical Y axis) |

M37 |

Unclamp saddle (horizontal W axis, vertical Y axis) |

M38 |

Clamp rotary table (B axis) |

M39 |

Unclamp rotary table (B axis) |

When you apply an axis clamp with M32, M34, M36 or M38, the corresponding servo motor is disabled (powered off).

When you release an axis clamp with M33, M35, M37 or M39, the corresponding servo motor is reenabled (powered on)

The clamps will all automatically be released (unclamped) on power-up, and at the end of any program cycle.

To use the clamps, you will need to write the appropriate codes into your CNC programs. For example, if you are using the B axis to index to position, and then want to use the clamps to hold it there, your program sequence would be something like this:

; various program startup codes G0 B0.0 ; move B axis to first position M32 ; clamp B axis and remove servo power ; various codes to perform the desired machining M33 ; unclamp B axis and restore servo power G0 B90.0 ; move B axis to next position M32 ; clamp B axis and remove servo power ; various codes to perform desired machining in second position ; ...

If you are writing your program with the Intercon conversational programming feature on the control, you can use Insert → Other → M&G Code to insert the axis clamp and unclamp M codes.

The control will automatically operate the way lube pumps periodically, when running automatic program cycles. The way lube system will not operate when the machine is idle, even if the hydraulic pump is running.

Machine Parameter 179 controls the interval between way lube cycles, and

the operating time for a cycle. The hundreds place of the

Parameter 179 value is the lube cycle interval in minutes. The tens and

ones place is the run time in seconds. For example, a value

of 2010 means to run the lube pumps for 10 seconds every 20 minutes

of program cycle time.

Jog Panel Summary

In normal operation, the Auxiliary keys on the jog panel have the following functions:

| Start or Stop Hydraulic System |  |

Work Light Off/On |  |

No function | |

|

No function |  |

Indicates touch probe trip |  |

No function |

|

No function |  |

No function |  |

No function |

| (Aux10) | No function | (Aux11) | No function | (Aux12) | Maintenance Mode On/Off |

The PLC program includes a "Maintenance Mode", which allows you to manipulate the gear changer components directly. This is primarily used in testing and troubleshooting.

To switch Maintenance Mode on or off, press and hold the Aux12 key for one second. Aux12 is the blank gray key in the right-most column, immediately below the Aux9 key. The LED in the Aux12 key will light up to indicate that Maintenance Mode is active.

You must cancel Maintenance Mode before you can again run normal program cycles.

In Maintenance Mode, the jog panel Aux keys have the following special functions:

|

No function |  |

Shifter slide #1 to left |  |

Shifter slide #1 to right |

|

No function |  |

Shifter slide #2 to left |  |

Shifter slide #2 to right |

|

No function |  |

Shifter slide #3 to left |  |

Shifter slide #3 to right |

| (Aux10) | No function | (Aux11) | No function | (Aux12) | Maintenance Mode On/Off |

| M0 | Stop (wait for Cycle Start) |

| M1 | Optional Stop (wait for Cycle Start) |

| M2 | Program Restart (with wait for Cycle Start) |

| M3 | Spindle CW / Forward |

| M4 | Spindle CCW / Reverse |

| M5 | Spindle Stop |

| M6 | Tool Change |

| M7 | Mist Coolant On (optional system) |

| M8 | Flood Coolant On (optional system) |

| M9 | Coolant Off |

| M32 | Clamp X Axis |

| M33 | Unclamp X Axis |

| M34 | Clamp head |

| M35 | Unclamp head |

| M36 | Clamp saddle |

| M37 | Unclamp saddle |

| M38 | Clamp B Axis |

| M39 | Unclamp B Axis |

| M41 | Shift to low gear (1-160 RPM) |

| M42 | Shift to 2nd gear (161-320 RPM) |

| M43 | Shift to 3rd gear (321-640 RPM) |

| M44 | Shift to high gear (641-1340 RPM) |

M functions M91 and above are used internally in custom macro programs, but are generally not used directly in user machining programs.

See Chapter 13 of the Centroid M-Series Operator's Manual for descriptions

of the higher-numbered M functions.

Machine Parameters Summary

The following parameters on the Centroid Machine Parameters table are used for features specific to this machine.

| Parameter | Meaning | Value | Notes |

|---|---|---|---|

| P57 | Load meter display | 63 | Show meters for axes 1-5 plus spindle |

| P179 | Way lube cycle timing | 2010 | Minutes of machine operation between cycles, and seconds to run pumps in each cycle |

| P902 | Machine format selection | 0 or 1 | 0 = horizontal milling, 1 = vertical milling |

| P961 | Spindle RPM for gear shift assist | 10 | RPM to bump motor while helping gears to mesh |

| P962 | Maximum Spindle RPM in vertical format | 600 | RPM limit of the right-angle head installed |

| P990 | Spindle load meter scale (Volts) | 10.0 | Analog volts from A1000 spindle drive, for full-scale motor load |

| P991 - P995 | Servo load meters scale (Volts) | -2.5 | Analog volts from Yaskawa servo drives, for full-scale motor load |

For all other Machine Parameter functions, see Chapter 14 of the

Centroid M-Series Operator's Manual.

Yaskawa Servo Drive Parameter Settings

Most servo drive parameters are set to factory defaults.

The following parameters are set to values other than factory defaults:

| Parameter | Value | Meaning |

|---|---|---|

| Pn000 | 0010 | Position control mode |

| Pn002 | 0100 | Use absolute encoder as incremental |

| Pn170 | 1400 | Disable tuning-less function |

| Pn200 | 0004 | Position control by A/B phases, 4x multiple |

| Pn20E | 1048576 | Electronic gear ratio numerator |

| Pn210 | 32768 | Electronic gear ratio denominator |

| Pn212 | 8192 | Encoder output cycles/revolution |

| Pn50A | 8101 | Disable P-OT input |

| Pn50B | 6548 | Disable N-OT input |

| Pn50E | 3200 | Remove /COIN and /V-CMP from output SO1 |

| Pn50F | 0100 | Put /BK (brake release) on output SO1 |

See the Yaskawa Sigma V series user manual for detailed

information on these and other servo drive parameters.

Troubleshooting

Any time the control cannot complete its tasks normally, it will display a message in the scrolling message box, in the upper right corner of the screen, explaining what went wrong. You can use the mouse to scroll up (back) in the message box to view the most recent 10 or so messages.

You can view older messages in the error message log, accessible from the F7/Utility menu:

Most common messages are described in Chapter 15 of the Centroid M-Series Operator's Manual.

The machine-specific PLC program can generate several of its own

fault, error and warning messages, in

addition to those listed in the Centroid operator's manual.

The machine-specific messages are listed later in this section.

PLC Diagnostic Display

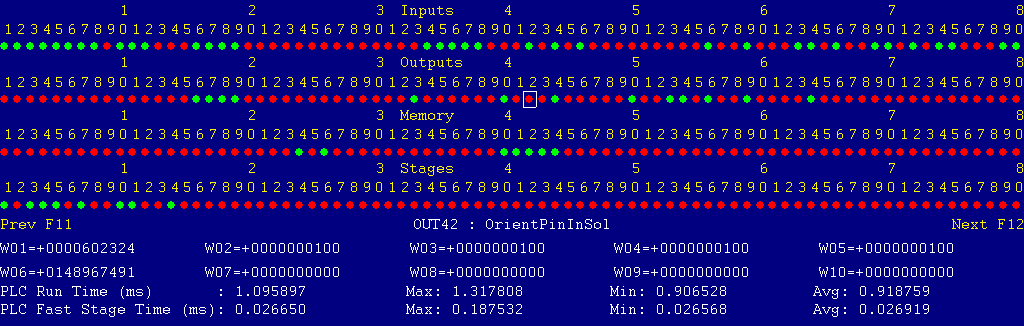

You can use the PLC Diagnostic display on the console to view some of the Centroid PLC input and memory locations mentioned with these fault and error conditions. At the control's main screen, press Alt-I to activate the PLC Diagnostic display. Press Alt-I again to dismiss it.

Each page of the Diagnostic display shows four rows of red and green dots: the first row shows PLC inputs 1 through 80; the second row PLC outputs 1 through 80; the third row PLC memory bits 1 through 80; and the fourth row PLC program stages 1 through 80.

You can use the arrow keys to move a highlight box over any of these locations. The name of the highlighted location will be displayed in the center of the screen below the red and green dots.

For example, in the illustration above the highlight box is on Output #42: The dot below the 2, to the right of the superscript 4, on the second line.

Below the four rows of bit status information are ten numeric ("word") variable values, labeled W1 through W10. Some of these variables also hold useful status information, described with the error and fault conditions to follow.

There are multiple pages of Diagnostic data. With the Alt-I diagnostic display showing, you can use the F12 and F11 keys to scroll right and left. For example, pressing F12 once will shift to the page showing inputs and outputs 81 through 160, and word variables W11 through W20.

Messages with 9000-series message numbers are Faults. After resolving the problem, you must press and release the Emergency Stop button to clear a Fault.

Messages with 8000-series message numbers are Errors. Errors will cancel the program cycle and stop the spindle and coolant, but they do not then need to be explicitly reset.

Messages with 5000-series and 2000-series message numbers are Warnings

and Informational Messages. They do not cancel the cycle or require

any action to reset.

Opening the Control Cabinet Doors

In some cases, it will be necessary to open the control cabinet doors while power is on. For example, servo drive and spindle drive fault conditions can be more readily identified using the codes displayed on, or stored in, the drive units themselves.

WARNING: Use appropriate caution when working in the control cabinets while power is on. Lethal voltages, up to 480VAC and 700VDC, are present on many components.

To open the right-hand control cabinet door while power is OFF:

To open the right-hand control cabinet door while power is ON:

When closing the right-hand door, make sure that the main breaker operator shaft properly engages the switch handle in the door.

The control detected an internal error in processing the PLC logic program.

Report this error to your dealer, along with the values from W14 and W15. Also report what function the machine was performing when the fault occurred.

You must shut down and cycle the power to clear this fault.

References:

PLC W14: Copy of internal SV_PLC_FAULT_STATUS, indicating the type of problem PLC W15: Copy of internal SV_PLC_FAULT_ADDRESS, indicating the location of the problem

One of the servo amplifiers is reporting a fault condition.

If possible, check the LED display on the amplifier itself, in the left-hand cabinet, to see the specific fault code.

See the Yaskawa Sigma V series user manual for detailed fault information.

Press and release Emergency Stop to clear the fault.

References:

PLC MEM16: Axis #1 drive status. Green = okay, Red = fault PLC MEM17: Axis #2 drive status. Green = okay, Red = fault PLC MEM18: Axis #3 drive status. Green = okay, Red = fault PLC MEM19: Axis #4 drive status. Green = okay, Red = fault PLC MEM20: Axis #5 drive status. Green = okay, Red = fault Schematic: Lines 12, 17, 22, 27, 33

The A1000 spindle drive (VFD) is reporting a fault condition.

This may result from over-voltage while decelerating, or from overload during spindle reversal (e.g. in a tapping cycle).

If the cause is not immediately evident, then check the LCD display on the spindle drive itself, in the right-hand cabinet.

You can review past drive fault conditions using the A1000 drive's monitor menu. The ten most recent fault codes are in monitor parameters U3-01 through U3-10. See section 5.11 and appendix B of the A1000 drive manual.

References:

PLC INP10: Spindle drive fault signal: Green = 1 = Okay, Red = 0 = Fault Schematic: Lines 6, 125

The control unit detected loss of communication from the operator panel in the console.

Check for damage or disturbance to the cables between the console and the Oak control unit in the control cabinet.

Press and release Emergency Stop to clear the fault.

References:

Schematic: Lines 90, 102

The operator panel reported back to the control unit a loss of communication from the control unit. This indicates the return signal from the operator panel is functioning normally, but the outgoing signal may have problems.

Check for damage or disturbance to the cables between the console and the Oak control unit in the control cabinet.

Press and release Emergency Stop to clear the fault.

References:

Schematic: Lines 90, 102

You exited the CNCM control software without first pressing Emergency Stop.

Always press Emergency Stop prior to exiting the control software.

Press and release Emergency Stop to clear the fault.

The CDBR dynamic braking unit for spindle drive reported a fault condition.

Press and release Emergency Stop to clear the fault.

References:

PLC INP15: Braking unit status: Green = 1 = Okay, Red = 0 = Fault Schematic: Lines 1, 128

The thermal switch in the regenerative braking resistor, on top of the right-hand cabinet, opened to indicate that the resistor is overheating.

Allow time for the resistor unit to cool down, and the thermal switch to close again.

Press and release Emergency Stop to clear the fault.

References:

PLC INP14: Brake resistor thermal switch: Green = 1 = Okay, Red = 0 = Overheat Schematic: Lines 0, 127

Float switch FS1, in the hydraulic tank, opened to indicate that the hydraulic oil level is low.

Check the oil level in the tank. Refill as needed.

Inspect around the machine for signs of leakage. The hydraulic system operates the axis clamps on X, Y, W and B; and it operates the gear-shift slides in the headstock.

The hydraulic pump motor tripped the overload relay (OL2) on its starter (M2).

Check the overload relay, lower right on the left panel, for a trip indication. Check the hydraulic pump and reservoir for possible causes of overload.

Press the white RESET button on the tripped overload. You may have to wait several minutes for the overload to cool before it can be reset.

Press and release emergency stop to clear the fault condition.

References:

PLC INP17: Trip indication from OL2. Green = 1 = Tripped, Red = 0 = Okay Schematic: Lines 37, 131

The headstock lube pump motor tripped the overload relay (OL3) on its starter (M3).

Check the overload relay, lower right on the left panel, for a trip indication. Check the headstock pump for possible causes of overload.

Press the white RESET button on the tripped overload. You may have to wait several minutes for the overload to cool before it can be reset.

Press and release emergency stop to clear the fault condition.

References:

PLC INP18: Trip indication from OL3. Green = 1 = Tripped, Red = 0 = Okay Schematic: Lines 39, 131

The drawbar motor tripped the overload relay (OL4) on its starter (M4F/M4R).

Check the overload relay, lower right on the left panel, for a trip indication.

Press the white RESET button on the tripped overload. You may have to wait several minutes for the overload to cool before it can be reset.

Press and release emergency stop to clear the fault condition.

References:

PLC INP19: Trip indication from OL4. Green = 1 = Tripped, Red = 0 = Okay Schematic: Lines 45, 132

One of the axis way lube pump motors tripped the overload relay (OL5, OL6 or OL7) on its starter (M5, M6 or M7).

Check the overload relays, lower right on the left panel, for trip indications. Check the associated lube pump and reservoir for possible causes of overload.

Press the white RESET button on the tripped overload. You may have to wait several minutes for the overload to cool before it can be reset.

Press and release emergency stop to clear the fault condition.

References:

PLC INP17: Trip indication from OL5, OL6 and OL7. Green = 1 = Any one tripped, Red = 0 = All okay Schematic: Lines 50-54, 132-133

The control lost communication with the PLC I/O expansion board.

Open the control cabinets and check for green "+5V" and "PLC OK" LED indications on the expansion board at the top of the left panel.

If either LED is not lit, check the connections at both ends of the gray cable which connects H8 on the Oak unit to H3 on the PLCADD1616 board.

References:

PLC W36: bitmap of detected PLC expansion boards. 1 = one board detected Machine Parameter 900: bitmap of expected PLC expansion boards. 1 = one board expected Schematic: Lines 107, 130

You attempted to start an automatic program cycle, but Maintenance Mode (Aux12) is still active.

Press and hold the Aux12 key for one second to cancel Maintenance Mode.

An attempt was made to run the spindle motor, either to start the spindle or to shift gear ranges, but the tool is not fully clamped.

References:

PLC INP32: Switch LS18 status: Green = 1 = Tool clamped, Red = 0 = tool not fully clamped Schematic: Line 139

An attempt to shift headstock gears did not successfully complete within the allowed time.

Use the F3/MDI prompt to try the shift again; or try shifting back to the previous range, then try shifting to the desired range again.

References:

PLC OUT27: Shifter slide 1 left solenoid (SOL1) status: Green = on = Slide 1 to left (low) position PLC OUT28: Shifter slide 1 right solenoid (SOL2) status: Green = on = Slide 1 to right (high) position PLC OUT29: Shifter slide 2 left solenoid (SOL3) status: Green = on = Slide 2 to left (high) position PLC OUT30: Shifter slide 2 right solenoid (SOL4) status: Green = on = Slide 2 to right (low) position PLC OUT31: Shifter slide 3 left solenoid (SOL5) status: Green = on = Slide 3 to left (low) position PLC OUT32: Shifter slide 3 right solenoid (SOL6) status: Green = on = Slide 3 to right (high) position PLC INP25: Shifter slide 1 right switch LS11 status: Green = 1 = Slide 1 in right (high) position, Red = 0 = Slide 1 not fully right PLC INP26: Shifter slide 1 left switch LS12 status: Green = 1 = Slide 1 in left (low) position, Red = 0 = Slide 1 not fully left PLC INP27: Shifter slide 2 right switch LS13 status: Green = 1 = Slide 2 in right (low) position, Red = 0 = Slide 2 not fully right PLC INP28: Shifter slide 2 left switch LS14 status: Green = 1 = Slide 2 in left (high) position, Red = 0 = Slide 2 not fully left PLC INP29: Shifter slide 3 right switch LS15 status: Green = 1 = Slide 3 in right (high) position, Red = 0 = Slide 3 not fully right PLC INP30: Shifter slide 3 left switch LS16 status: Green = 1 = Slide 3 in left (low) position, Red = 0 = Slide 3 not fully left Schematic: Lines 135-138, 140, 179-184

The PLC program requested display of a message on the screen, but the provided message code was not valid.

This indicates an error in the PLC program. Report the message to your dealer, along with the value in PLC variable W16.

References:

PLC W16: stores the invalid message code

The PLC hardware detected the presence of an I/O expansion board, but the setting of Machine Parameter 900 did not tell it to expect that board in the system.

On this machine, there should be one I/O expansion board installed, and Machine Parameter 900 should be set to 1.0.

References:

PLC W36: bitmap of detected PLC expansion boards. 1 = one board detected Machine Parameter 900: bitmap of expected PLC expansion boards. 1 = one board expected

No fault condition is present, but the hydraulic system and headstock lubrication pump have not yet been started. You cannot operate the machine until you start the pumps.

Press the HYDRAULIC PUMP (Aux1) key to start the pumps.

A previous servo drive fault condition has been resolved, and cleared with Emergency Stop.

A previous PLC fault condition has been resolved, and cleared with Emergency Stop.

You inadvertently pressed a keyboard combination that is used for keyboard jogging controls, but keyboard jogging features have been disabled on this machine.

A previous fault condition has been cleared with Emergency Stop.

The hydraulic pump and headstock lubrication pump have been started. The machine is ready to operate.

The report_0417180586_vertical.zip and report_0417180586_horizontal.zip file sets that are restored when switching machining formats contain the following files:

| cncm.prm.xml | Machine Parameters | Servo drive and encoder mappings, format selector |

| cncmcfg.xml | Machine Configuration | Axis labels, drive ratios, backlash compensation, etc. |

| cncm.wcs | Work Coordinate Systems | Axis travel limits and G28 return points |

| homelog.txt | Record of axis home-search distances | Needed because Y and Z are different physical axes |

| report_*.txt | Human-readable record of configuration values | For reference only, has no effect on operation |

Because these files in the control are replaced with the archived files every time you switch between horizontal and vertical formats, any changes that you might have made in Parameters, Configuration, Work Coordinate Systems, or logged homing distances will be lost on the next format switch.

If there is a need to make changes in any of these areas, and have those changes preserved in the future, then you will need to update the archive file(s) that are used in format switching.

To update one of the archive file sets:

If appropriate, switch formats and repeat the above procedure for the other format.

The order of the axis drives; order of the axis definitions in the control configuration menus; and order of the axis jogging controls can vary. Definitions for this machine are as follows:

| Horizontal Format | Vertical Format | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

These codes usually only need to be entered once. They are stored on the control a file named cncm.unl.xml. They should be kept on file in case that file is ever lost.

Serial Number: 103199 -- Key A (plain): 0417180586

The following are necessary to unlock software features:

| Option | Parameter # | Parameter Value |

| Scales | 232 | 28045.4234 |

| Permanent Unlock | 298 | 59085.4811 |

| Intercon | 300 | 62925.8644 |

26-Jul-2019 MBL